The NF EN 12825 standard explains the technical criteria for raised floors (slabs, pedestals, measurement and testing methods) . It was created in January 2002. It has been created and adopted by all recognized European manufacturers.

The NF 57.1 standard applicable to markets defines the conditions of implementation and the contractual fields of raised floors. This standard was modified in September 2007, then in May 2020.

Like any French DTU, 57.1 includes 3 parts, called P1-1, P1-2 and P2.

These standards are available from standards management organizations

standard. Don’t hesitate to order them from them.

You will find below the main guidelines of DTU 57.1

It applies to all French climatic zones and does not cover the overseas departments and regions.

1. – Links to other standards & vocabulary

In addition to the NF EN 12825 standard, the NF DTU 57.1 document specifies in §2, the references to other DTUs including:- NF DTU 21 applying to concrete works,

- NF DTU 53.1 applying to textile floors

- NF DTU 59.3 applying to floor paints

2. – Characteristics

The characteristics mentioned here are detailed in the reference standard.

2.1 – Requirements before work

- Premises kept out of water and out of air

- ambient temperature: 12 to 24°C, humidity 45 to 70% (storage and work)

- Materials made available according to a delivery and installation schedule

- Plans specifying the characteristics of all structures surrounding the floors

- Provision of lifting means

- Clear and secure spaces to allow supplies and handling in strategic locations: the floor elements must be stored as close as possible to the premises to be installed (even climatic conditions).

- Acoustic, fire, electrical and level requirements are clearly defined before the construction site

2.2 – Compliance with standard NF EN 12825

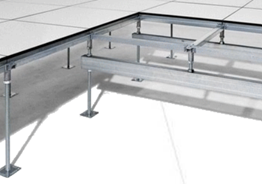

The DTU recalls the technical requirements for projects and in particular compliance with the technical characteristics mentioned in standard NF EN 12825 (load classes), and in particular the notion of RESISTANCE TO VERTICAL FORCES.

2.3 – Nature of the soil

The DTU recalls the specific characteristics of (raw) concrete slabs and in particular the concerns due to their surface condition.

The nature of the ground therefore influences the height of the plenum, and the supports must be accepted before installing floors: resistance to weights, resistance to static and dynamic loads, resistance to forces transmitted to the base of the jacks, resistance to tearing of parts stuck to the support.

2.4 – Traffic

The DTU recalls a very important directive.

“No traffic other than that of the company is permitted on the raised floor during the work and at the earliest 48 hours after the end of installation…” (in order to guarantee bonding.

3. Implementation

The requirements for maintaining temperature and humidity are recalled, as well as the criterion out of water, out of air.

3.1 – Anti-dust paint

If it is carried out, the paint (DTU 59.3) must be taken into account for compatibility with the floor to be installed.

The floors must be free and dusted.

3.2 – Assembly

The DTU then recalls key elements for the installation including:

- Requirement for a general materialized level (NGF)

- Definition of layout start axes

- Edge slabs (on the periphery of the installed floor): they will be at least 100 mm

- Start of installation never on the edge: in the center, on one side, or a corner of the area to be installed

3.3 – Finishes

- Edge slabs and cutouts around obstacles: they must be installed after complete adjustment of the solid slabs

- The framework must be prepared to receive the slabs

- If equipotential connection, it is authorized to assemble it gradually and not at the end of the project

- The accessories are installed at the end of the phase

- The company must clear the site of products related to its service

- The company, after having verified its installation, must request a contradictory report to be carried out with the project owner to validate the service.